Why you need Machine integration

Expensive machines and production lines deserve to be utilized fully, and in the right way. But to do this, you need to know what can be improved. Machine integration (MI) can do it all, from capturing data from your machines to identifying actual rates of utilization.

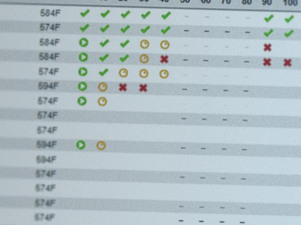

Monitor’s Machine integration provides a clear visual overview of your machines.

Examples of data from your machines that MI can capture.

- Start and stop

- Stop causes

- Number of details produced

- Rejections

- Warnings

Four reasons to use Machine integration

MI is vital for us in order to do things the right way.

MI Limited

Machine Integration includes a function called MI Limited. This allows you to connect a machine without including order management and time tracking in Monitor. MI Limited is a flexible solution within Machine Integration that gives you control of how you want to use the system to optimize your production.

MI is key for Readycare Manufacturing

Gone were the uncertainties of achieving production targets, replaced by real-time insights that allowed them to identify areas for improvement and make strategic decisions to streamline their operations - thanks to MI.

Frequently asked questions about Machine integration

How does MI work?

Your machines communicate with MI via an OPC or PLC device which interprets the signals from the machine and reports them to the ERP system.

You’ll also need an MI server and a machine terminal for each machine. You can then connect as many dashboards as you like.

Which machines is MI compatible with?

In simple terms, you can say MI works with all machines that can communicate via OPC or PLC. Some types of machines can connect better than others. Contact us so we can look at your facility together and identify the best solution.