Alfapac chose Monitor ERP to pinpoint production

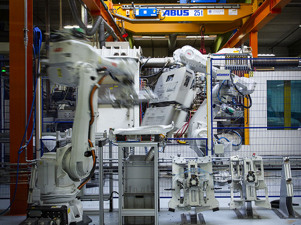

Alfapac is a manufacturer of plastic industrial packaging, including different types of sacks, bags, and plastic covers used to protect and package other products. Take a tour around the factory in Åsbro, however, and you’ll soon realize plastic isn’t always just plastic.

Certain plastic films comprise several different layers, in order to achieve the qualities required by the customer. The production process involves mixing different types of plastics, or “formulas”, which are then put together in thin layers. Mats Olson, CEO and son of the company’s owner, gave a brief outline of how it all works.

“The process actually involves just two different stages: we melt the raw plastic material and make a thin plastic film which is rolled onto large rolls. When the roll is full, we set it up in the next machine and cut it into short pieces, creating a bag, sheet, or sack,” he explains.

With headquarters based in Åsbro, outside Örebro, the company also operates in Kumla and Billingsfors. Alfapac has around 85 employees in total, and turns over just north of SEK 200 million annually.

Although its customers are mainly based in Scandinavia, Alfapac’s products are sold as far afield as China and Central America, among other areas.

“I think the reason we’ve grown over the years is that we've been able to adapt to the requirements of our customers,” says Olson.

There’s also a depth to the system which we can utilize when following up our production, and in reports,” he adds.

Alfapac replaced its existing ERP system with Monitor G5 in 2020. This was due to growing dissatisfaction with its previous supplier.

“We chose Monitor for a number of reasons. We were already familiar with the system, having looked at Monitor G4 last time we were considering a new ERP system 12 years ago. At that time, though, we didn’t think it could give us everything we needed. But we felt that, with Monitor available in a new version – G5 – it would prove a good fit for the company.”

Much of the implementation project took place remotely, due to the Corona pandemic, and Financial Manager Marcus Kindevåg gave it the seal of approval.

“The project went really well. We received professional service from Monitor’s consultants, in my view, who demonstrated great expertise within their fields. The system went live on August 1, and we were prepared for a number of problems in the beginning, but we solved them quickly – quicker than we’d expected.”

According to Marcus, Monitor is clearly a system designed for manufacturing companies.

“You can see how it’s adapted for purpose, and easy to figure out when navigating fields and menus. There’s also a depth to the system which we can utilize when following up our production, and in reports,” he adds.